MG-Cars.info

MG Midget and Sprite Technical High Lift Rockers BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

MG Midget and Sprite Technical - High Lift Rockers

| Anyone any experience of these? http://www.minispares.com/product/Classic/Engine/Cylinder_heads/Rocker_Assemblies/C-AHT436.aspx Rob |

| MG Moneypit |

| I have the roller tip high lift rockers...mine are part of a complete high high performance rebuild... i love my engine and wouldnt change a thing i cant say how much the contribute ... only that they do To be honest... its a cheap alt to replacing the cam.. its simpleand easy to do on a sat morning in the driveway. Id certianly recommend it Prop |

| 1 Paper |

| I have a 1.5 roller rocker assembly which I got from Avonbar all those years ago. . . .very well made, and whilst I changed a number of things at once so therefore cannot say what the mod contributed directly, it was recommended by a certain Mr Vizard, and that's good enough for me |

| P Bentley |

| I would go with the purple ones from Minispares for £100 more. Non roller tip rockers wear the valve guides and I would guess this is exaggerated the more lift you have. They are really well made and make a noticeable difference. If you have an alloy rocker cover you need to relieve it inside so they clear. I think the standard rocker cover will fit ok though. |

| John |

| I have the purple rockers... and they are very well made, i was hesitant at first seeiing how the rollers where attached, but they work fine and ive never heard of a failure in the tips Yes the alloy cover does need to be relived not hard to actually remove the alloy as it barely touches just enough to make noise ... its finding where the contact is being made thats most difficult On roller tip rockers..when setting the lash with the feeler gauges swipe rhe gauge in and out from the side, while manipulating side to side NEVER from the front, back and forth as the roller will obsorb the tolerance and give you a flase readiing Also it helps to cut your feeler gauges down so there much narrower and put a 60 degree bend abiut an inch from the tip... it makes it so much easier to insert the gauge from the side Prop |

| 1 Paper |

| We also have the purple roller tipped 1.5:1 rockers. Have been on now for almost 60,000 miles and no problems. We have a Piper BP270 cam and the standard tappet clearances for the cam are 0.012" for both inlet and exhaust. After extensive problems many years ago with 'nipping' exhaust valve(s), we run the inlets at the recommended +0.003", i.e. 0.015", but the exhausts at 0.018", to give a little more 'seat' time. No obvious tappet noise and very pleased with both cam and rockers. Richard |

| Richard Wale |

| I had a set of these on my engine for a while. Nicely made though I took them off again and sold them. I found them noisy in use and the engine seemed less torquey at lower revs which for twisty hilly roads where I drive is not what I wanted.

|

| GuyW |

| Guy Good point... i talked to perter Burguss about this same issue when i was building my engie and he advised to advance the cam a few extra degrees and mine is very torque On my SW5 swift tune cam it the stat sheet said to time to 106 degrees and i set it to 102 degrees ... i think it has to do with the valves having to travel an extra .25 inches longer ... so to open the valve .25 inches plus close the valve .25 inches equals 1/2 inch of extra travel total.... thats going to take some extra time to complete compared to the stock rockers of 1:1.25 so by advancing the cam timimg so the vales open and close eariler as it relates to the postion of the piston you compensate for the extra time that the valves have to travel Sorry guy...i didnt mean to infer that your 5 years old i know you knoe that stuff ... i just didnt know how to get out of this comment and still make the case on how to compensate for a weaker torque if you have high lift rockers Prop |

| 1 Paper |

| No Prop, you are right and that is very valid. I did in fact do exactly that and retimed the cam according to the recommended with additional advance for the high lift rockers. I wasn't saying the high lift rockers didn't work well ('though they were noisy). Power was increased but this happened at higher revs and for my type of use and the roads around here it wasn't really what I wanted. Given that I also have a 5 speed box the engine isn't really pushing the revs at M-way speeds either so overall I was more interested in useable lower engine speed torque than higher rev power. |

| GuyW |

| Thanks guy Thank you for not thinking i was being condescending toward you... i do respect your abilities Sure i can see your poing of view... i have no idea to what level of tune the high lift rockers actually provide as i built my engine all at one time rather then piece meal... all i knoe is it gets up and moves pretty quick compared to before the rebuild You are correct about the noise, somethimg i forgot about as i just learn to accept all the lack of modern day niceitys I belive the lifter noise comes from the rollers themselves as to how they are attached to the rockers...its just a simple roll pin acting as the axle that holds them on and it has alot of play buit in, i orginaly saw that and considerad modifying thst to a better quality... but its not an issue as people are now reporting as much as 60,000 even 80,000 with no issues so in the words of the Beatles, i just let it be , but i really think thats the source of the noise Prop |

| 1 Paper |

| Prop, at first the noise was really loud - but that was because one of the rockers was kissing the inside of my alloy valve cover. A common fault I understand. Once I had ground a bit of extra clearance from the inside of the cover it was a bit less noisy, but still quite a bit louder than standard rockers (not sills to you!) |

| GuyW |

| Cam timing? I had always set the Piper 276 with 4° advance on the recommended timing, with 1.5:1 rockers as well. Very strong bottom end, and pulled cleanly through to 7000rpm and more (self limited to 7000, but very easy to go above!). When I rebuilt the engine with a 'new to me' block 3 years ago, I changed the cam to a Piper BP270, which has similar timing, but a bit more inlet valve lift. Talking to Piper they said to time it 'straight up', so I did. It has much less lower down grunt, and needs to be up to 3000+ rpm to really get going. Similar top end performance, but I now have a proper electronic rev limiter at 7000rpm, with a shift light at 6800rpm, both courtesy of the Nodiz ignition module. I have to put on the rollers to find out the full story, but on a small sample, I think 2-4° cam timing advance may be good for lower down torque - both these cams are nominal '276', so not designed for low down grunt. If I have to take the timing cover off for any reason, as I have a 'vernier' cam drive, will reset the cam timing to 4° advance. Richard |

| Richard Wale |

| Same as mine then Richard, a 276 cam with 4 degs. Extra advance. Pulls well from low revs but became peaky with the high lifts and an extra 2 degs advance (6 total) above standard. That's why l reverted. |

| GuyW |

| Thanks for all your views. My reason for asking is I have a couple of tappets which are persistantly noisy which I cannot improve by adjusting the gap so I'm putting it down to wear in bushes or shaft. I have the solid sintered rockers from a late Mini which apparently are only 1.2:1 ratio rather than the commonly assumed 1.3:1. I had considered new forged rockers and uprated shaft which would be closer to the intended 1.3:1 ratio but when you price it all up for individual parts it comes out close to the 1.5:1 rocker set in the link I posted. The cam I have installed is a 286, the engine is +60 with single HIF44, standard MG Metro head and is installed in a Frog with a Type 9 gearbox and 3.7 diff. It feels very nippy and despite the lumpy idle it is quite driveable even at 30mph. I'm no Lewis Hamilton but the red mist does descend sometimes when the pillock in the BMW hugs my rear bumperettes like he is trying to mount my luggage rack. Did those who have tried 1.5 rockers and retimed the cam do so because of a marked deteriation in driveability? Or was it to wring out a few more BHP? So I was really asking specifically about the rocker set in the link in my first post, but most seem to go for the roller rockers when going to 1.5:1 but it's just a bit too far financially for me. Any more opinions will be welcome. Rob |

| MG Moneypit |

| Standard 1275 rockers are 1.25:1 - at least, the pressed steel variety. I was led to believe that the sintered ones were the same. |

| Dave O'Neill 2 |

| Rob, if you have the sintered ones try this before changing anything. Before you set the valve clearances get your 0.012 feeler gauge and file it down at the sides to make the tip narrower than the valve stem. If I get time I'll send a pic. Basically the valve stem wears into the soft sintered rocker tip and so when you put your standard width feeler gauge in it just bridges the wear and gives you a false reading. So if you use a 0.012 feeler but you have say 0.005 wear on the tip you will actually end up with 0.017 clearance. Those sintered rockers are pretty poor to be honest, the pressed steel ones are much better. |

| John |

| If anyone wants any pressed rockers, let me know. I think I have at least one set of 1275 rockers and several sets of 1098 rockers. |

| Dave O'Neill 2 |

| The sintered ones are the same. They have to be, unless the pedestals came with them and are different from standard. |

| Nick and Cherry Scoop |

| If you are in fact running at 1:1.2, and not 1:1.3 or 1:1.5 Wow... you are going to be in for wild time, esp with that engine set up |

| 1 Paper |

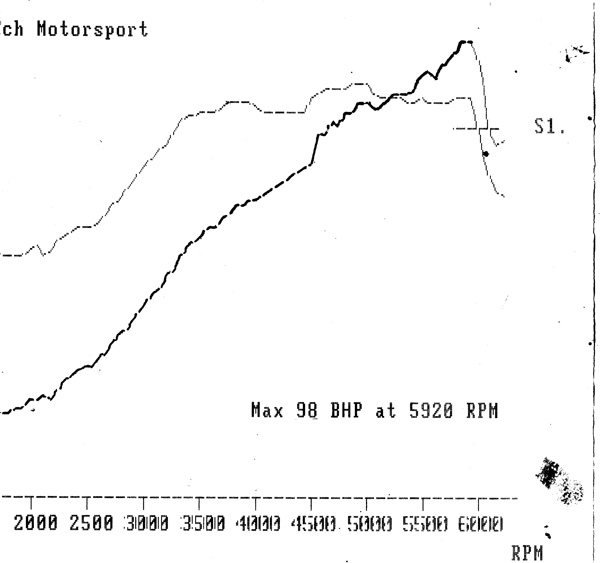

Well I'm a fan of sintered rockers. I've had high lift rockers,offset bushed rockers and both were clattery and wore pads and shafts quickly, and seemingly needed regular adjustment. The new sintered ones with a 286 are virtually inaudible and simply never need any adjusting. I may be 'losing' 2 or 3 brake at the top end but I wouldn't revert back. Far better I think to spend your dosh on a rolling road session. For the same price you'll get your advance curve, fuelling and induction properly tailored to your engine needs, pick up more power throughout the rev range with better economy,and probably extend the life of the engine as well. This engine gave 98 BHP @ 6000 RPM at Hi-Tech Motorsport.

|

| F Pollock |

| Rob I had some of those Minispares forged hi-lift rockers so time ago and they were terrible with tremendous wear on the tips/pads after less than 2000 mile. After examining the damage Minispares said they were a batch that had slipped though without being hardened properly and replaced them. I tried the purple roller rockers but try as I could I could not prevent them fouling the rocker cover (I tried every type of A-Series cover including some claiming to be specially for hi-lift roller rockers). Eventually I reverted to the Minispares hi-lift forged rockers again and so far after a lot of miles and high revs on track days they still seem OK (only time will tell). They certainly make a huge difference if used in conjunction with other mods. I got 109 bhp on the Aldon rolling road. PS I don't think the pressed steel rockers are safe for high reving engines - I had some come apart after a track day and that was when I changed to forged rockers. |

| Chris Hasluck |

| The pressed steel ones are quite good if the Vizard suggested mod of running a weld along the top is done. I did that to mine and the engine was regularly run to 7k RPM on occasions and no issues. |

| David Billington |

This thread was discussed between 25/04/2017 and 02/05/2017

MG Midget and Sprite Technical index

This thread is from the archives. Join the live MG Midget and Sprite Technical BBS now