MG-Cars.info

MG Midget and Sprite Technical Pulley nut removal BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

MG Midget and Sprite Technical - Pulley nut removal

| My clutch slips so front pulley removal is difficult. I think I read somewhere that someone wedged the crank in the sump previously. The sump oil is out and its coming off anyway so that could be tomorrow. Any advice on what to wedge where to stop crank turning and therefore remove pulley nut? Could do with not breaking the crank case on this one before the next engine and gearbox are ready. Cheers, Dave. |

| Dave Squire 1500 |

| Dave I haven't heard of the crank way But with a slipping clutch I have taken out the starter motor and used a bar between teeth on the ring gear. Hope it helps and good luck |

| Dave Pratt |

| Dave, An alternative is to remove the starter motor and wedge the ring gear from moving when you undo the pulley nut. I have an old angle bracket (5-6mm plate bent 90deg filed a bit to fit teeth - or use thinner steel) - was actually an old spot light mount i think - I use to wedge into the starter ring teeth and fixes in place of starter fixing bolt - using the same bolt to stop engine rotating. Dave O'Niel has posted a pic previously of his version. R. |

| richard boobier |

| Thanks both, I remember now you mentioning this a few weeks ago ish. Its an easy make tomorrow morning. I have the other engine on the floor to easily make the piece to fit without crawling about the car to fettle to fit even. Materials and tools to hand. Thanks again, Cheers, Dave |

| Dave Squire 1500 |

| Dave, I was always worried about chipping the ring gear trying to hold it there. I guess you don't have an impact wrench, which would solve the problem. Another method is put a big breaker bar on the bolt and prop the end of the bar on a wood block or frame member or floor, and then crank the engine with the starter. It will be loose in a split second. Another method is to feed several feet of soft flexible rope into a spark plug hole, then turn the engine until the rope stops the piston from further travel. Do this with the valves closed on the cylinder of choice. Be sure to leave enough rope hanging out of the hole so you can retrieve it. Charley |

| C R Huff |

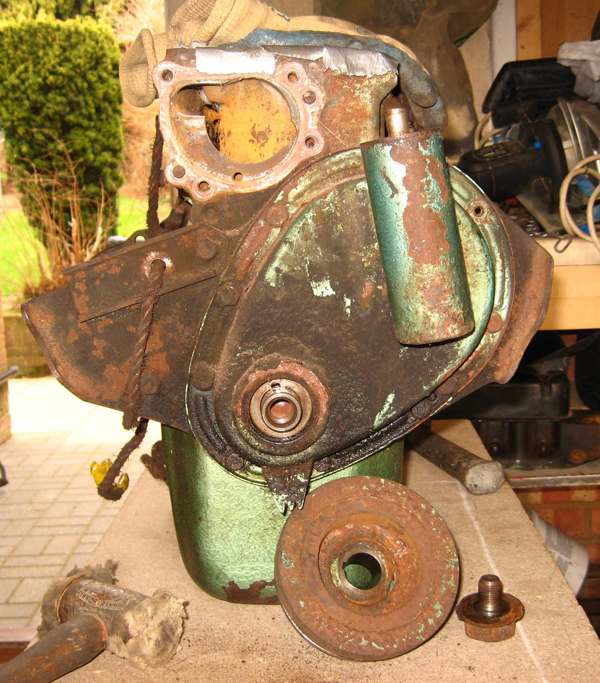

| Someone call? Here's mine... Bolt it through one of the starter holes and lock it into the ring gear. It works best on an A-series using the lower hole when undoing and the upper hole when tightening. ISTR that the 1500 starter is on the N/S so you would reverse the procedures.

|

| Dave O'Neill2 |

| Here's an easy way. No need to lock anything. Put a socket on the pully nut. Plug the T bar in so the arm is horizontally extended to the left. Place a length of wood vertically onto the end of the T bar, long enough so that it extends up to a point where you have clear access to it. Hit the end of the wood with a heavy hammer. One good hard hit will undo the nut. Works every time for me. |

| Lawrence Slater |

| Yeah, if sump is off just wedge the crank with a good chunk of wood (or two inch steel box section!) and give the nut some welly! No worries. Hope you have had a good Christmas Dave and others! Malcolm |

| M Le Chevalier |

| I would use Malcolm's method - a piece of 2" or bigger timber jammed between crankshaft and block will safely lock things from turning. A blow on the wrench is the easiest way to unlock the thread, as Lawrence said. Trying to undo it by simply applying force is very hard work. But if you have access to a powered impact driver, the thing comes undone in seconds. Air tools can be brilliant. |

| Mike Howlett |

| No need to remove the sump or wedge anything. If placed and hit as I described, the stationary crank, flywheel, and pistons, will offer sufficient resistance that the nut will undo. Inertia. That's how I undid my pully nut, with the engine sitting on the bench, with the sump on, and the head off. |

| Lawrence Slater |

Like so. But I didn't need the length of wood as I had direct acces to the nut with the engine out of the car.

|

| Lawrence Slater |

| Lawrence, The 1500 will require a bigger hammer ! as the nut is a higher torque than the A series - 150 - the 'A' being 70lb ft R. |

| richard boobier |

| Same hammer, just hit it harder. ;). A 4lb lump hammer should do it. |

| Lawrence Slater |

| That is one job that completely failed me, and several others who tried it on my previous car, Morris Minor with a Marina engine in it. Tried all the above, to no avail. Even tried wedging a 1 5/16" spanner on, having it about 60 degrees up from the floor of the engine bay, which was jacked from beneath onto a concrete floor with 2/4 timber, then tried the starter method. "works every time" I was told. It didn't. To this day, as far as I am aware, it still has the plain nut rather than the starter dog I had wanted to put in it's place! I reckon copious amounts of loctite were used..... |

| Dominic Excell |

| I must admit, I used the socket with T bar against the cross member and a flick of the starter method. Works a treat for me. |

| Pete Ottewell |

| I use a modified "Lawrence" method, removed the mounts, jacked the engine up then lowered the pulley back down on to a lump of wood , a good socket, a t-bar a good clean smack with a hammer took three blows, but worked last time. Malc and a Happy New Year to all !!!! |

| Malc Gilliver |

| hi just another method...if you are able to.......borrow a 12 volt impact wrench as used by mobile tyre fitters to remove truck/tractor wheels. One second burst of the gun job done rgds tony |

| a boyle |

Lots of great advice guys, but nobody has advised how to tighten the nut again after the job is finished. Dave |

| Dave Barrow |

| I think I did ;o) |

| Dave O'Neill2 |

| Lawrences impact method will work... its the impact that removes it... or you could use an impact driver... Or use a special tool where starter motor gos... I made one from a bar of steel... drill 2 holes to take the starter bolts... cut and file a tooth to mesh with the ring gear... bobs your uncle. See photo attached |

| Christian Carter |

with photo

|

| Christian Carter |

This thread was discussed between 29/12/2013 and 01/01/2014

MG Midget and Sprite Technical index

This thread is from the archives. Join the live MG Midget and Sprite Technical BBS now