MG-Cars.info

MG Midget and Sprite Technical Weird misfire problem BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

MG Midget and Sprite Technical - Weird misfire problem

| Hi All,

Since I fixed my heater, my car has been running well, until now… I had a sudden problem with the engine running on three cylinders, and it was No 2 cylinder that was at fault. However, pulling the plug lead slightly off and holding the middle of the cap against the plug terminal restored correct running, albeit I could hear the spark jumping from the cap to the terminal. As the leads were about 10 years old, I replaced them and problem solved, or so I thought - the car ran properly a few days ago. HOWEVER, the same issue was back on the same cylinder this morning. And it can be “solved” in the same way – by taking the lead slightly off. Any ideas? I am baffled!! Could it be a plug issue? James |

| James30 |

| Yes. How old are the plugs and are they a decent make? Try swapping them round see if that makes a difference. If the plug is ok it could be the 'riveted rotor arm' problem. Best to check. |

| Jeremy MkIII |

| Certainly check your rotor arm and plugs as suggested, NGK plugs are generally considered best. Also how old is your dissy cap, what's its condition? All the items mentioned are often overlooked until problems arise but even if they're working they can be passed their best or optimum. Checking, cleaning (and gaping) them regularly as part of a service will help to keep them in good condition and the engine and it's performance as best it can. |

| Nigel Atkins |

| Sounds like a dead/dying plug to me Shorting out inside and when you create a spark gap by pulling the lead off a tiddle it reduces the power at the plug and it doesn't short it self internally--plug lead back on ,more power retuns and so does the short/missfire Hope you weren't pulling that lead by hand ------------Plastic pliers------ willy |

| William Revit |

| Topic drift (sorry) how's the shoulder doing, Willie? |

| Martin |

| Good thanks Martin I've had a couple of decent crashes mountain bikeing that tried things out a bit and it appears bullet proof----so far The only restriction with it really is I can't get my hand up my back but we can live with that Thanks for the thought willy |

| William Revit |

| Willy, I was thinking that creating the air gap would cause a higher voltage spark at the plug. Wouldn't the extra resistance from the air gap wind the voltage up higher in the coil to allow it to bridge the gap? Charley |

| C R Huff |

| I'm thinking I got it round the wrong way Charley- I reckon you're right same overall result----dead plug Cheers willy |

| William Revit |

| Thanks Jeremey, Nigel, Willy, Charley. The dissy cap and rotors around 10 years old, the plugs are newer and are NGKs. Hmmm, I will buy a new set of plugs and swap them out. On the dissy cap/rotor, I should probably replace them too... ... is the quality of modern caps/rotors good enough or should I look for NOS? Only other point is the plug gap. I have electronic points and a 'Flamethrower' coil. They've been perfectly reliable - is there any need to increase the gap on the new plugs? |

| James30 |

| Swap over the suspect plug with one of the others and see if the fault moves with it. |

| GuyW |

| I had an NGK fail after a couple of years. They are generally excellent but there is always the risk of a rogue one. It was similar to your experience James. new set cured it. |

| Bob Beaumont |

| James,

test and if required replace one part (or set like plugs) at a time if you want to know what's causing your problem. The quality of dissy caps and particularly rotor arms can vary very much. Getting NOS isn't always reliable because it depends on the NOS quality as poor quality goes back many years. Before replacing try inspecting the rotor arm and cap first, with a magnifying glass if you have one, looking for cracks on the plasticy bits and gouges on the brassy bits, mind just because you can't see them doesn't mean they aint there. First clean inside and out, don't transfer muck from the outside to inside the cap though. You could clean the bassy parts with very fine wet'n'dry glass paper if required or just use a clean pencil rubber if they're in good condition, wipe out and debris though, you could finish off with an electric contact cleaner if you wanted, I'm not sure but I don't think WD40 is a good idea for this, it's a water disperent really and might leave a coating of stuff you don't want. Even if the rotor arm and/or dissy cap weren't the problem personally I'd change them anyway, with good quality replacements of course. There are others but the only supplier I feel safe recommending is the Distributor Doctor particularly for his red rotor arms - beware not all red rotor arms are equal - http://www.distributordoctor.com/red-rotor-arms.html As his caps seem out of stock at time of writing you could also try simonbbc or Mister-Auto. Let us know how you get on. |

| Nigel Atkins |

| ETA: if you've got a good spark via coil, 'points', rotor, cap, leads and plugs then a wider gap could be useful if everything else is set up and running well |

| Nigel Atkins |

| NGK plugs suck...i used to like them but in recent years they went down hill badly and foul at the drop of a hat

The champions work really well as do the AC DELCO brand If you got a newer egintion system ...dissy, coil, points and im assuming leads ...then no i wouldnt repalce thst Bug id lay good money its the spark plug When you replace the plugs... do it cold, tighten the plug slightly before unscrewing it to break the seal in the between the plugs and the cly head threads and use anti sizure compound on the threads of the new plugs...just in case your not aware Prop |

| 1 Paper |

| I have to say, that's the first time I've ever heard anyone say anything bad about NGK plugs. |

| Dave O'Neill 2 |

| Thanks to Nigel, Dave and Prop for their thoughts since my last post, and especially to Willy who was spot on. It was the plugs.

Must admit I also hadn’t heard that NGK’s were awful, I’ve used them for years. Anyway, that’s what my local supplier had, I swapped them out and – bingo – the car was restored to the fun-to-drive state that I remember. It certainly looked like changing the HT leads and plugs would have to have been done anyway. When I removed the plugs, all four looked a little sooty, suggesting running a little rich, but certainly doesn’t feel like it when driving and I don’t know if this could have been caused by all the plugs beginning to fail. Will monitor and adjust as necessary - at least the carbs appear balanced. Thanks again to the group for helping me solve this! |

| James30 |

| As an aside, Charley's suggestion about a gap between the plug lead and plug increasing the voltage at the plug is interesting (well, to me.....). I would say that the HT voltage is determined by the turns ratio of the coil i.e. it is fixed. An additional resistance in the secondary (HT) circuit would, in theory, lose some voltage across it meaning there would be less voltage at the plug producing a weaker spark. That would actually tie in with Willy's suggestion i.e. that the plug was actually producing a better spark with a plug lead gap given that the plug appeared to have an insulation fault, if you see what I mean. |

| Bill Bretherton |

| Well done on sorting it James. Swapping parts around or out can often help resolve an issue - but never assume a new part isn't possibly faulty. I think the very few exception with NGK plugs possibly proves the rule of favouring them. I certainly don't believe in changing parts for the sake of it but changing service parts after they've passed their optimum can often help to keep the car running well and nearer to better performance. |

| Nigel Atkins |

| Yes, well done James. Good to know it was something simple and easily fixed with a few coins!

Whilst Bill and Willy are exchanging their knowledge on the electrical characteristics of the spark plug I am going to pose another question which I have often wondered about. - One can visibly check a spark plug is sparking by removing it and laying it on the edge of the head whilst spining the engine. But is the spark different when back in the engine and performing under pressure? Does this make any difference? Are the gas molecules closer together, making the spark easier to leap or do the tightly packed and hot molecules just get in the way? |

| GuyW |

| Just remembered, if you're going to replace the rotor and/or dissy cap, I previously got a NOS Lucas dissy cap, in a Lucas green box, that looked decidedly odd with lacquered copper looking posts. I sent it back and Mister-Auto.com gave me a full refund and thanked me for bringing it to their attention. The rotor arms I got from them were spot on though. I've also got reliable parts from premier-factors. |

| Nigel Atkins |

| Obviously I don't have a clue about the answer but think the same sort of thing. Jumping across it with my own thought (sorry Guy). I think Guy's question also ties in with what I've put about changing parts - generally visual checks can give a yes/no, on/off type of answer but often very little further details. A part can visually look OK and might work OK but it doesn't mean it's working well or at its best. And back to Guy's question . . . |

| Nigel Atkins |

| I was thinking along exactly the same lines as Bill, but hesitated to express it. What Bill says makes a lot of sense to me: output voltage (HT) is determined by the coil ratio and the input voltage (LV) to the coil, nominally 12V. |

| Peter Blockley |

| Actually the potential peak voltage will be governed by the turns ratio but the actual peak voltage is governed by the voltage required to jump the spark gap under the cylinder conditions so will be lower. |

| David Billington |

| Sorry Guy, don't have a clue. Bill lost me at 'determined by the turns ratio of the coil' so best let him, David and Peter thrash it out between them :) |

| Jeremy MkIII |

| What have I started.........?

I agree with David. The maximum HT voltage, determined by the turns ratio, will probably not be reached. When the points open, the existing magnetic flux in the coil collapses rapidly and this change induces a voltage in the secondary HT circuit (the coil is an electrical transformer consisting of a primary coil of so many turns of wire magnetically linked to a secondary coil of many more turns where voltage is proportional to no. of turns) which will rise rapidly until it is sufficient to jump the plug gap. I'm no chemist but, alluding to Guy's question, this sufficient voltage depends upon conditions in the combustion chamber such as temperature, fuel/air ratio, compression level and humidity. So, holding the plug in free air doesn't indicate performance in a working cylinder but only whether the plug might work. Clearly James's plug didn't work properly "under pressure". |

| Bill Bretherton |

| Bill,

I had a problem with my first VW Passat and that was misfiring and sometimes power loss, it was evidenced by sparking from the plug metal shield to the head on occasions and that got tracked down eventually to the servo hose having perished and it was leaking and making the engine run lean which makes the plugs harder to fire so was sparking to the head rather than across the plug gap. I'm not sure if it's pertinent but I widened the gap on my lawn mower recently and it runs far better as that should result in a higher spark voltage, shame the other bits of the mower seem to be failing, may have to borrow my neighbours mower for the last mow of the year or fix the recoil assembly. |

| David Billington |

| Recently, David? We haven't had good enough weather to mow the grass for ages. |

| Nick and Cherry Scoop |

| Interesting David. I've done some reading as a result of this thread to determine how combustion conditions affect ignition e.g. a lean mixture requires a higher spark voltage which may lead to misfire as the coil cannot cope with that demand as you found. It would have been easy to blame the plugs or the coil or the condenser (or electronic module) in that case, all of which would have been incorrect.

Before On Board Diagnostics, mechanics would often throw parts at the problem until it went away. With a classic car it pays, of course, to understand how the ignition, electrical and fuel systems work from first principles. |

| Bill Bretherton |

| Hold on. I thought the classic symptom of a weak mixture was pinking. I.e. the engine fires prematurely on the upstroke of the piston. Fires early = fires before it has built up such a fat spark? = At a lower voltage? |

| GuyW |

| On the voltage thing-----

A normal ignition coil has the capacity to provide aprox. 40,000 volts---roughly Now, at idle, depending on the plug gap it will take about 20000 to initially jump the gap and less than that to maintain the spark until the capacity of the coil is exhausted All good so far-- Then by introducing an extra air gap the coil will need to release a higher voltage to jump the gap--keeping in mind the coil can give 40000 if needed ---On the scope ,which is taking it's measurement from the coil output it will show a higher spark voltage depending on the size of the gap--we'll say 30000 ish for our gap and the burn time voltage will be slightly higher as well but lots shorter as the coil can only empty out so much Result--with air gap-- Initial spark voltage-----Higher Burn time voltage---slightly higher Burn time duration---much shorter Therefore we have both more voltage but less spark------------measured from the coil But I'm not convinced that this is what happens in practice What I'm interested in now is what is happening to the voltages 'after' the introduced air gap, at the plug which will have to be measured at the leed after the air gap Over the weekend I'll get my scope out of hiding(thought I'd never use that again) and have a play and report back willy Most spark plugs die from either an internal or external breakdown in insulation, tracking down the outside or a buildup of crap or cracks on the centre insulator Usually the buildup is caused by either a plug that is too cold or mixture too rich when the plug is cold causing a coating to build up on the insulator which eventually causes tracking (shorting) |

| William Revit |

| My suspicion is that the conditions of pressure, fuel strength, atomisation and temerature inside the cylinder have little direct effect on a 20,000v + spark jumping a 25 thou gap. But that they will have a big impact on the actual combustion and rate of flame spread. And of course indirectly effect the spark progressively by oiling or carbon build up on the electrodes.

This effect of creating an extra "external" spark gap - there is already at least one extra spark gap in the circuit at the rotor/ dizzy posts. |

| GuyW |

| I agree with Willy in that most plugs play up due to insulation failure. I think the reason that they can appear to work when removed is because they are usually cold. When in place and working they are hot and the small cracks which cant be seen open up and cause the short. No doubt all the other things mentioned above contribute to helping with this but I think that is the main reason for failure. Trev |

| T Mason |

| Guy, I don't know the answer to your point about a lean mixture causing pinking thus suggesting pre-ignition conflicting with me saying MORE voltage is required for a weak mixture. I think it's complicated. A higher temperature requires lower spark voltage, I think, so it may be that sometimes, a lean mixture increases the temperature in the cylinder a lot such that it has more effect on combustion than does the lean mixture itself. There are a lot of variables so it's hard to know. As I said, I'm no chemist.

Willy, I await the results of your experiment with interest. Trevor, you may well be right. |

| Bill Bretherton |

| Yes, Bill. I should have said "maximum" output voltage. But from there on, I bow out, but find it all makes for very interesting reading. |

| Peter Blockley |

| Bill My scope's lost it's leeds somewhere-new set should arrive in a couple of days- Sorry for the delay but I'm trying to get the old jigger up and running properly after an extended storage session willy

|

| William Revit |

| "My scope's lost it's leeds somewhere" Yorkshire, maybe? I'll get my coat ;o) |

| Dave O'Neill 2 |

| Willy

I have an old Scopex model 14D-15 in the garage by my "electronics" bench, which is fired up occasionally. I last used it to check the output waveform from my MIG welder. I'm interested in audio and have built various amplifiers and other stuff over the years plus I have a classic 1974 hifi amp (Cambridge Audio) so the scope comes in useful now and then. Look forward to the spark plug experiment. I confess to having not thought it through properly i.e. the spark normally occurs before maximum potential coil voltage is reached so, if an additional gap is introduced, you would think the coil voltage would need to get higher. This would imply a later spark i.e. slightly retarded ignition for that cylinder.

|

| Bill Bretherton |

| Guy,

With respect to your comment on plugs firing in free air but not in the cylinder: Champion used to make a tool for shops that combined spark plug sand blasting with spark plug testing. The system was connected to shop compressed air, which drove the sandblaster. Then, for the plug testing, the plug was screwed into the machine and a lead connected to it. For this test, the shop air subjected the business end of the plug to air pressure to simulate being in the cylinder. It was explained to me that a plug might fire in free air, and fail to fire under compression. I don't know how fully the machine mimicked the real world. With regard to the air gap issue, a friend older than me showed me a road grader that was missing a bit. He pulled the coil wire out a bit from the cap, and it smoothed out. He said it used to be pretty common to pull the wire and put in an eraser cut off of a pencil, and then replace the wire. He said adding resistance is what caused it to smooth out, though he said nothing about voltage. This probably all related to solid copper leads. Charley |

| C R Huff |

| The air gap in the HT leads is an old dodge. I remember seeing an Austin 7 in the 1960s that had each HT lead cut in half and the bare ends looped through a plastic coat button - each bare end through each of the two button holes. Must have looked interesting when running in the dark. Les |

| L B Rose |

| Sorry Charley, l had missed your interesting message from a few days ago until l saw Les' post just now. Quite a lot of HT leads used to incorporate a resistor as some sort of radio interference surpressor. And there is of course already a built in spark jump gap at the rotor arm. Austin 7s used to oil their plugs very easily. Maybe the extra spark gap would help combat that in some way? Perhaps increase the plug spark temperature or something? |

| GuyW |

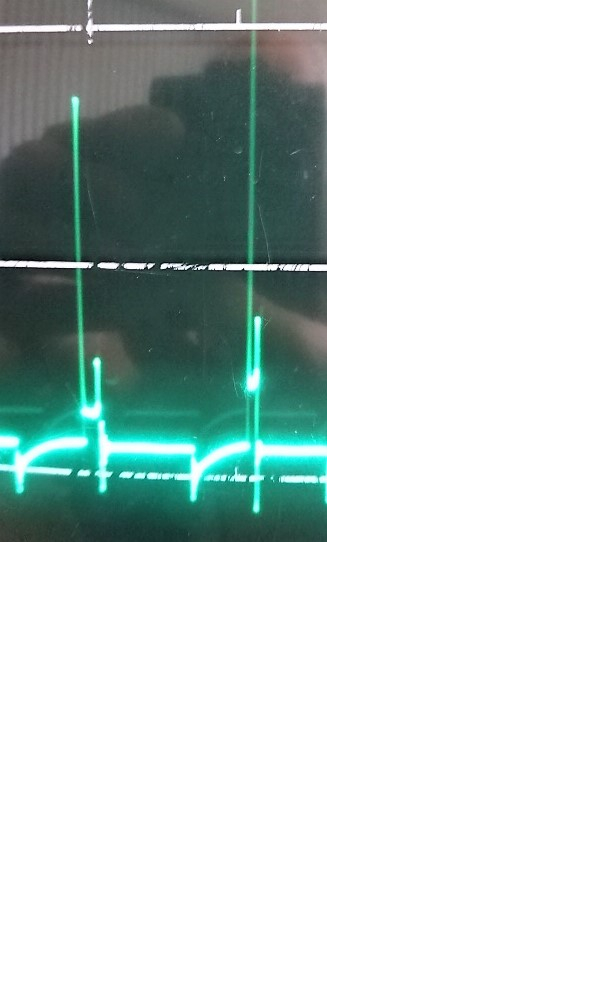

| Bill NOW I'm confused Got the scope going and hooked it up to my Elan as it's my only petrol car, not the best choice as they get warm fairly quickly just idling, so I'm planning to borrow a mate's Jag for more extended fiddling -- Anyway , first off here's a pic of two cylinders at idle showing approx 16000 volts and 11deg of crank rotation burn time (that's another story, not being much of a photographer,trying to get the picture to time in with the pulses of the scope)

|

| William Revit |

| Next- measured from the coil lead again, is with an air gap introduced between the dist. cap and the plug lead to the cylinder on the right There was no measurable difference to spark timing on this cylinder with the timing light but as the pic shows, voltage from the coil went sky high, the burn time voltage was about 2000v up as well but burn time reduced from 11deg to 6deg as the extra voltage output from the coil reduced available time-

|

| William Revit |

| Then, I connected the pickup onto the pluglead up near the plug after the introduced air gap-

As sort of suspected the voltage went back down to the original 16000v which I was thinking would be what was required to jump the set sparkplug gap under the same idle conditions but the surprise was no measurable burn time-just an instant 16000v zap All I can think at the moment is that the introduced air gap eats up the extra voltage and also eats the reduced burn time down to almost 0 resulting in a smaller/quicker spark at the plug gap itself I'm still not convinced what's happening but when I can borrow the Jag and spend some more time on it ,i might be able to talk myself into believing something plausible Here's the 16000v sparkline, and the next pick is of the rest of this sample showing no burn time or after firing oscilations back into the lead

|

| William Revit |

Can't get the last one to load but it's just a little spike and no oscillations probably because we have no direct sensing from the coil output from on the outside of the air gap

|

| William Revit |

This thread was discussed between 17/10/2017 and 08/11/2017

MG Midget and Sprite Technical index

This thread is from the archives. Join the live MG Midget and Sprite Technical BBS now