MG-Cars.info

MG MG Y Type MIG welding BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

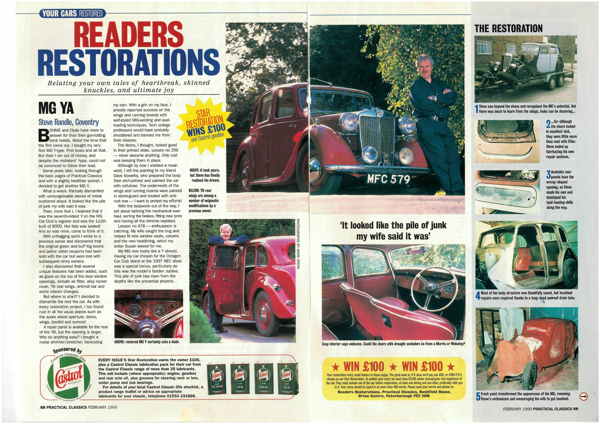

MG MG Y Type - MIG welding

| Haqving had a bit of a shock re prices of body repairs these days i am thinking of buying a DIY MIG welder for under £200- I am told that latest ones (eg Clarke 90EN gasless) can do car bodywork reapirs..anyone got any experience on a Y type with one of these..damn sight cheaper than getting a body shop in..I am not looking for perfection just to do some repairs at the rear end of the body. |

| D MULLEN |

| I'd say go for it! Some day I will try welding myself, too. But remember that good welding takes a lot of practice and preferably a course at a technical school. |

| Willem van der Veer |

| I bought a clarke 90 mig 15 years ago and have done full restorations on:- mg midget,morris 1000 van, land rover,morris minor and currently mg y type. My MOT tester always comments on the quality of my welding. The clarke has been no trouble at all.I use the one which uses gas and use co2 as used in pubs and it costs £20 for a refill which lasts me 18 months, hope this helps, Graham |

| Graham Sharpe |

| I have used a MIG and also Oxy/Acet for body repairs for more years than I care to recall. The basic difference to keep in mind is that MIG filler wire produces a very hard weld that is difficult to hand shape and finish, so the angle grinder is always close at hand. So you really need to do all your beating/shaping before the welding. But it is very fast, and you can quickly learn to control heat deformation with carefully placed tack welds. On the other hand, a gas weld filler wire is nice and soft and can be hand beaten and hand filed easily after welding. The gas kit can also be used for shrinking and stretching - two things that a MIG cannot do. However the price of gas and bottle rental makes it very expensive for a hobby workshop these days. Get the MIG, do a bit of practice, and you will find yourself very satisfied with the results once you get the hang of the adjustments. Just make sure the MIG has a low AMPERAGE setting for sheet metal (many are really only suitable for heavy structural steel). Tony The Classic Workshop Black Mountain |

| A L SLATTERY |

| ....how much did he quote you Dave...? Rob |

| Rob King |

| To do a decent job you may need more that a mig welder as I found out. Like some pieces of angle iron to act as a metal bender, a joggler to ensure the surface lies flat and one of the most useful tools was a shrinker/stretcher. https://www.machinemart.co.uk/shop/product/details/edge-setterjoggler-with-hole-punch http://www.eastwood.com/shrinker-stretcher-set-one-body-two-jaws.html Then you need to either use filler or lead to get a good flat finish. Its been over 20 years since I completed mine but its lasted and was worth every cut, bruise and burn I got.

|

| Stephen Randle |

| Have a look at the CEBORA range Dave, i had a arkwelder for50years and a mig for twenty good strong brand.I prefer the gas to gasless it sounds like you are going into panel repair i have a couple of doors with 18 inches orso missing!! interested in a job??!! |

| JC Jebb |

| I am also a boat builder by the look of my slipup.!! previous posting should read arc welder put it down to my age and the weather |

| JC Jebb |

This thread was discussed between 01/10/2014 and 26/11/2014

MG MG Y Type index

This thread is from the archives. Join the live MG MG Y Type BBS now