MG-Cars.info

MG TD TF 1500 Looking for backing plate bolts BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

MG TD TF 1500 - Looking for backing plate bolts

| I am in need of one shorter front backing plate bolt and 4 longer (3/8 x 1 5/16) rear backer plate bolts. All the larger suppliers in the US and UK are out. These have the rounded shoulders. |

| Bruce Cunha |

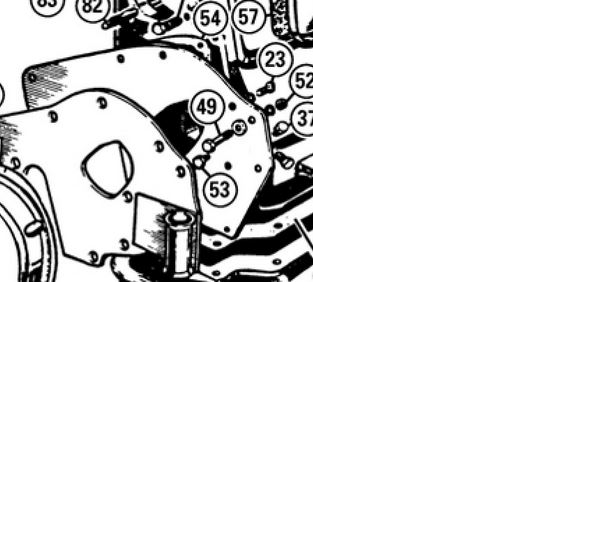

| Here is a picture. I am also in need of two of the early front hub grease felt retainers. Not the later cap, but the early felt retainer.

|

| Bruce Cunha |

| Do you mean #23 320-260and #53 320-260 ? But those are M8x1mm and length is 16mm (5/8) and I guess the heads are modern ISO type and not rounded. MOSS Europe do have them in stock.

|

| W_Mueller |

| I think Bruce is looking for the hardware to attach the brake backing plates to the front spindle and differential tubes. |

| W A Chasser |

| okay anglo parts has them in stock for the rear axle - the price is EURO. https://www.angloparts.com/de/catalogues/show/18/mgtd-tf-1949-1955

|

| W_Mueller |

Bruce, I sent private email to you. |

| Richard Cameron |

| Bruce, give me a call--I have a question for you about these bolts 270-384-0344 |

| Richard Cameron |

Bruce, It seems the rear ones I have don't have a rounded edge. However, the front ones do. |

| Richard Cameron |

Brown & Gammons also have bolts (BSF and UNF!)in stock. They are cheap and picture shows ISO heads.

|

| W_Mueller |

| Thanks all. Not sure on the Anglo ones, they don't give a picture, but their kit is well up there in price. The NTG do not look like they have the correct cut to the flats. Can't really tell. Looks like Richard has what I need. I can make these on my milling machine. The cut is easy, but the setup is a bit and you have to do it 48 times. If I can figure out a quick way to cut the angles, I will turn out a batch so we have more available. |

| Bruce Cunha |

| This is why a small centre lathe should be part of a T Series tool kit. It would only take minutes to to reduce the thickness of the bolt heads and form a dome using one. I have made up a jig for my Myford lathe to clean up the threaded ends of bolts when bits have been sawn off to shorten them. Nothing looks worse than a rough, sawn off end, especially if the saw cut has been stopped three quarters way through and the redundant bit broken off leaving a large burr. Cleaning them up on a grinding wheel, possibly with an uneven and exaggerated chamfer is just as ubsightly.

Jan T |

| J Targosz |

|

Are these what we are talking about? My Disc Conversion kit had metric bolts with full flat heads. As Jan-T noted you could turn the heads on a lathe with little effort to duplicate the look. As I remember these had BS heads on them so most likely mad metric. However it looked to me like full heads would not have a fitment problem. If wanted I could measure and supply a sketch, Jim B. p.s. I had to recover, a bit, from a hospital stay before I could go down to the garage to take a picture. Still wobbly.

|

| JA Benjamin |

Bruce, note the type nuts Jim B. shows in his image from the front ones. Like mine --plain BSF nuts & lock washers. |

| Richard Cameron |

| Richard and I were having a discussion on if the front axle to backing plate bolts had regular nuts or Philidas nuts. Rear had Philidas nuts, but in all the factory pictures I have seen, I cant tell about the front. A frame I am using to identify nuts and bolts, it has Philidas nuts in the front. None of the cars I have found on line have Philidas. The lathe is a great idea. I have a great lathe (Monarch 10E), but not a lot of experience. So, this will also be something for me to try. |

| Bruce Cunha |

| Hi Bruce, With a little practice you will be able to work the cross slide and saddle feeds dual handed and form the domes free hand. Be VERY careful though the bolt heads will be close to the chuck so keep your fingers away from the rotating jaws and no loose sleeves. Have a good Hogmanay, Jan |

| J Targosz |

| Bruce, All of the TD/TF cars I have seen had the Philidas nuts on the back, and regular nuts with the thin lock washers on the front. Seems if they ran out of one type of nut the other could be substituted on the line? George |

| George Butz III |

| Quote; The lathe is a great idea. I have a great lathe (Monarch 10E), but not a lot of experience. So, this will also be something for me to try. End Quote; Attached picture shows my process. Tool is 60 degree V for threading. Not quite the same since I am leaving a spud to be milled square but close enough. Its still a stud. You could also use a turning tool and set the compound at 30 degrees. Jim B.

|

| JA Benjamin |

| Thanks Jim. The Monarch has a tapering feed on it. One of the items I have wanted to learn to use. These are so slight a taper, it should be fairly easy to cut. |

| Bruce Cunha |

| That was fun. Thanks Jim. I set up just like your picture, using one of my original bolts for my angle. Once I had that I took off metal until the center of the bolt was exactly the same size. Here is the lathe with the bolt in it.

|

| Bruce Cunha |

Here are the finished bolts along side the original.

|

| Bruce Cunha |

This thread was discussed between 25/12/2018 and 02/01/2019

MG TD TF 1500 index

This thread is from the archives. Join the live MG TD TF 1500 BBS now