MG-Cars.info

MG TD TF 1500 Original Replacements for Tacho Gearbox Hex Rivets BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

MG TD TF 1500 - Original Replacements for Tacho Gearbox Hex Rivets

| The original steel rivets were a peened hex head that actually accepts an Allen key. Problem is the entire unit turns, head, washer and the end of the rivet at the back. The fixing was presumably never meant to be reused as the gearbox was like many original components, a repair by replacement item. I'm sure stripped gears can be replaced but how to reproduce/reuse the fixings without resorting to a bolt and nut set up? Cheers Peter TD 5801 |

| P Hehir |

| Peter: Do you have a picture of an original? I have been running replacements for 50 years so I cannot comment on what I have never (remembered?) seeing. |

| Christopher Couper |

| I used to have a box of NOS originals (long since sold), and they all had perfectly-flattened rivet heads. There was no sign of a hex anywhere. Tom Lange MGT Repair |

| t lange |

| Yes I can provide a pic of the drive that I have. I assume it's original. I've had it for ages and it's one of the things that I was going to get around to fixing. The one that works is on the car. The repros have no numbers. This is marked R 141 2 - 25 1. I'll post the pic later. I have a pretty full day today. Cheers Peter TD 5801 |

| P Hehir |

| I have a NOS Smith's tach drive on my TC, installed a few years ago. Smooth rivets. |

| Steve Simmons |

| I have had mine since 66'. It is a replacement , later engine. Drive could come from the early 52 engine, thats long gone, or the late 52 engine I have.

It carries the same numbers as yours BUT it has round heads on the rivets. I never disassembled it. It was frozen solid when I reinstalled it about 6 years ago, I soaked it in KROIL and kept working it. I got it o turn freely and kept spraying KROIL into the lube hole until the residue was clean. It's now running on a very low viscosity teflon based greas/oil. Trying to disassemble it looked to be too much work. Jim B.

|

| JA Benjamin |

| Thanks Jim. They look similar. It's difficult to clearly show the hex head but an Allen key of the appropriate size fits perfectly. I guess my gears are stripped as it is free but nothing from the output side. See pics of front and back. Cheers Peter TD 5801

|

| P Hehir |

| Peter - I think your unit is a rebuilt original unit (not a reproduction), with replacement rivets. The one with the plain, flattened, round rivets are the original type I have seen, and which my box of NOS ones had. Tom Lange MGT Repair |

| t lange |

| Hi Peter, Just checked my TF and mine has the hex head with Allen key fitting. But I know mine is not original as I bought it to replace my old one in 1969. Hope this helps settle any misconception's as to what is the original. Cheers John |

| J.K. Chester-Freeman |

| This pic shows the Allen key inserted into the rivet head. Tom if it was rebuilt, which may well be the case, then I'm stymied as to how the Allen head was pressed over the washer below it? This is what I'd like to remove and reuse when the internal gears have been replaced. I too think it's original, perhaps earlier than the TD or even the TC? Cheers Peter TD 5801

|

| P Hehir |

| We just cross posted John. So it's a 60's replacement unit? Cheers Peter TD 5801 |

| P Hehir |

| Just to clear up any ambiguity. Bought brand new in box from Auto electrician in 1969 as replacement for my damaged original. Cheers John |

| J.K. Chester-Freeman |

| They look like hollow head rivets that have been clenched with an eyelet punch. I have just done some TD snap fasteners and the hex shape is there. Ray TF 2884 |

| Ray Lee |

| I guess the chances of reusing these are remote. Are the hollow headed rivets that you mentioned readily available Ray? I have a case with a set of about 300 different tips for a wide variety of heads and perhaps if I could source the appropriate rivets I may be able to use one of the hex heads as a punch? Suggestions welcomed. John when you mentioned it was new in the box was this NOS? Was it the same as your defective unit? Cheers Peter TD 5801 |

| P Hehir |

| Found this link which suggests that one of these may make an ideal replacement.

https://www.google.com.au/search?q=hollow+head+steel+rivets&dcr=0&sxsrf=ALeKk03WFde-ZahV9tfYUEUd06CrMmXT_w:1597838636591&tbm=isch&source=iu&ictx=1&fir=sRkv2y97-iZKnM%252CF0mujiWKOqOn7M%252C_&vet=1&usg=AI4_-kRnzl55wVoDPrjQfOG8kmYGJiVxbQ&sa=X&ved=2ahUKEwi8o97inKfrAhXHzDgGHUKjBGUQ9QEwA3oECAoQIA&biw=1920&bih=966#imgrc=sRkv2y97-iZKnM. They would have to look much more authentic, especially with the punched hex head to secure the washers. Certainly better than the usual nut and bolt approach. I'll check out the available sizes. I may have to buy a quantity so if anyone here is interested let me know. My OS email issue still isn't resolved though. Cheers Peter TD 5801 |

| P Hehir |

| Peter. Now you are really stretching my memory 51 years.. sadly all I can remember was the unit went in for repair. Was informed that it was unable to be repaired. Have no idea if it was due to lack of parts but when I went into the workshop was advised they had a new replacement in stock, Back then I wasn't as interested in its origin just the fact that I had a working replacement. Sorry can be of no further help. Cheers John |

| J.K. Chester-Freeman |

| Thanks muchly John. I'll run with it from here. Hope you're getting back to your old self. A few TTORC members have been in the wars of late, me included, hence the delay with the August issue. Cheers Peter TD 5801 |

| P Hehir |

| I think you would have to get them turned for you. Most hollow head rivets are used in things like switches and other electricals and are specialist items. If you can get them you can buy a punch cheaply from a haberdashery (if that word is still in use) ;-} As I said, they are used for clenching snaps and shoe lace rings. Ray |

| Ray Lee |

| (Shoe lace rings "!x%4$?@:) BRAIN FADE!!!!!!, the word I needed was eyelets. Ray |

| Ray Lee |

| An offline suggestion is to try using a jewelers screwdriver and a small hammer to gently tap each of the six sides in towards the centre just enough to release the washer. Depending on the result it may be possible to then reuse the rivets. Failing that, after notating a set of measurements using the digital vernier (an essential tool I've found), I'd have a good starting point to search the link above, where I'm hopeful I'll find rivets that will do the job. They have a huge range. If so on assembly I'll spread the head with a suitable hex headed tip used as a punch. Thanks all for your posts. I'm keen to see what condition the gears are in. I know the ratio so it may be possible to have some gears made, if that is indeed the problem. If anyone has a defective unit that they want to get rid of please let me know. Cheers

Peter TD 5801 |

| P Hehir |

| Couple of issues. The link above is incorrect. It just takes you to 'hollow'. Flat head tubular semi hollow rivets don't seem to exist in either MS or SS. Looks like a machining job if I can't reuse the rivets. Cheers Peter TD 5801 |

| P Hehir |

| Peter Locate a good saddler or boot repairer they may have what your looking for or know a supplier. I chased every where for side curtain rivets and this was the supply solution. Graeme |

| G Evans |

| Peter, The bigger problem will be finding the gears. They are not a standard modulus size. If damaged you may have to have them made. Regards Declan |

| Declan Burns |

| Yep Declan. I figured that. "I'm keen to see what condition the gears are in. I know the ratio so it may be possible to have some gears made, if that is indeed the problem." Acetyl seems to be the best modern gear material with better durability than brass. Should be possible to have them injection moulded, produced in a CNC machine or 3 D printed. Cheers Peter TD 5801 |

| P Hehir |

| Peter, This company may be able to do it. They made brass gears for Thierry Suchier to repair his speedo. They are based in Poland. I would use steel gears like I do on my speedo corrector gearboxes. https://shop.kkpmo.com/product_info.php?language=en&info=p21680_zahnrad---kundenspezifische-sonderanfertigung.html&=&XTCsid=b8687r4jij7u7vks1k60uikpk1 Regards Declan |

| Declan Burns |

| Peter, Thierry Suchier measured the gears on his TF . One big one 27.15 mm diameter 4mm thick 54 teeth. One small one 12.15 mm diameter 4mm thick 24 teeth. Ratio 2.25:1 Regards Declan |

| Declan Burns |

| Thanks Declan. Those measurements are most appreciated. I have been given 3 original tacho drives all of which are seized. I won't know the cause until they arrive and I have them apart. The sourcing of the steel flat head rivets is the first task. Pan head tubular semi hollow steel rivets are available here in Sydney and it may be possible to linish the heads flat. Otherwise I'll have to have a batch machined up. I hadn't considered steel gears. Acetyl was my first choice as it has great mechanical strength and chemical resistant properties. Cheers

Peter TD 5801 |

| P Hehir |

| Peter, The link only goes to google and shows results for "hollow". If you have found rivets with correct dimensions it would be great if you can share the source. |

| John van den Boorn |

| I don't know what happened there John and Declan. Once I find the correct link again I'll post that. It's Friday evening here so it wont be until next week. Cheers Peter TD 5801 |

| P Hehir |

| I've some time today to hunt for these steel rivets again. This much I know. They are steel round flat heads that are semi hollow. Any further info re head diameter, shaft diameter, washer thickness OD and ID, length etc., would be much appreciated. Cheers Peter TD 5801 |

| P Hehir |

| Toolfix in Sydney have steel, circular, flat head, semi hollow (tubular) rivets. Waiting on confirmation on head and shaft diameter, though they look to be about the correct size. They are 7/8" long so the hollow will have to be drilled deeper and the excess length cut off. Cheers Peter TD 5801 |

| P Hehir |

| Just disassembled a tacho gearbox that wasn't working expecting to find stripped gears but they look perfect. No real reason that I can see as to why when turning the input, the output shaft doesn't turn. I'll investigate further. It was full of black grease but it hadn't hardened so shouldn't be the reason it wasn't functional.

Some metric dimensions follow for those interested in pursuing steel tubular rivets with solid flat heads. Head thickness is 2 mm Head diameter is 7 mm Shaft diameter is 4 mm Washer diameter is 8 mm Washer thickness is a bit less than 1 mm. I'll measure it tomorrow. Toolfix in Sydney may have some. Now that I have the dimensions I'll call again tomorrow. They don't list steel tubular rivets on their site but they do carry a small range. The length is not an issue as they can be drilled using the existing hole as a guide to the depth required in a drill press and the excess then cut off. Peening using an Allen key or a bit with a hexagonal profile should suffice. Cheers Peter TD 5801 |

| P Hehir |

| I don't know if mine is original; but it has a "smith" marking on it. Ref is nearly the same 141 AT/17 2 25 1. Hollow hex rivets. I think that this hex shape is just the shape of the peen hammer. Laurent. |

| LC Laurent31 |

| No joy with Toolfix or with Davco, the big supplier here in Oz. It seems these will need to be turned up on a lathe or they may be able to be purchased over the counter in China. Or it might be possible to reuse them, though I very much doubt it. At least the washers can be recycled. Here's a pic. Cheers Peter TD 5801

|

| P Hehir |

| When I was working on my gear reduction unit, I noticed that the rivets Looked more like snaps than rivets.

The corners of the hex appeared to be slotted. I felt that, perhaps they were arranged so the washers could be pressed over and snap into place. I was going to try to make a tool to force them closed so the washer could be slipped off and the “RIVET”? removed. However cleaning the assembly in KROIL freed it up and removed all crud and I never pursued this. My unit was frozen solid. Soaking it took care of everything. Jim B

|

| JA Benjamin |

| The latest suggestion was to try CNC milling but that sounds like an expensive process unless you were making a few hundred. I doubt there would be a market for that sort of quantity even worldwide. Cheers Peter TD 5801 |

| P Hehir |

| The first CNC quote I've just received is $20 per rivet, minimum quantity 20. That's way out of my league. Cheers Peter TD 5801 |

| P Hehir |

| Peter For a limited job run, which is all you require, I would be considering machining these out of 4 mm machine bolts selected so that there is sufficient non threaded section. When opportune give me a ring and I will discuss how I can assist. Graeme |

| G Evans |

| Will do mate. Sounds like a nice bit of lateral thinking. Call you tomorrow. I wrote a reply to your post on the missing bolt, but it vanished into the ether before I had the chance to send it. I #$@%^&$%* hate computers! Cheers Peter TD 5801 |

| P Hehir |

| Great talking with you today Graeme. I've ordered 20 of the 4 mm screw bolts that you've suggested and with a bit of fettling using your method it just might work. Cost including postage is less than $4 AU. I could find no suitable semi tubular steel rivet anywhere. The standard apparently since 1969 for solid and semi tubular rivets makes finding one with a head that is 2 mm thick impossible. Happy to be proven wrong though. If successful using the basic equipment that I have (no lathe unfortunately), I'll write a piece and publish it in the TTORC mag.

Just 43 vacancies left now as we're capping at 200, otherwise we fall into a higher public liability and personal injury insurance bracket. The invitation to BBS followers to join still stands; although preference now though is for those who reside here in Australia and New Zealand, providing they are owners of those cars from the M Type to the TF 1500. pjbm (at) bigpond (dot) com still works for the time being, however please note I've changed email addresses. I mentioned in an earlier post above that the head accepts an Allen key. Obviously that was a typo. It's the tail that is peened. The head is smooth. Cheers Peter TD 5801 |

| P Hehir |

| This does look like the simplest method to turn a drill press into a lathe for the purpose of drilling a short 3 mm hole down the centre of a solid 4 mm rivet about 18 mm in overall length. The excess couple of mm can be trimmed prior to peening. https://vik-olliver.blogspot.com/2010/02/drilling-down-middle.html. Graeme's suggestion to start with an item with a 4 mm unthreaded length of shank and a 7 mm circular head that is deep enough to be reduced to 2 mm thick, is the key.

The use of the term “forward’ in the link though has me slightly concerned. Because we are now working upside down, should I be using a left hand 3 mm drill bit? It seems a slow speed is the way to go. My Hare and Forbes drill press has a huge range of speeds so I'm able to set it on the slowest speed possible. This task is a big ask and I do realise this. Turning a solid 4 mm shaft into a semi-tubular rivet, leaving just a wall thickness of 1/2 a mm, even to a depth of just 5 mm, suggests that a great many things could go wrong. Something that should be a doddle on a lathe requires a careful and methodical approach using a drill press. What makes this just possible is that the hole needs only to be deep enough to ensure that the wall can be peened over sufficiently to trap the rivet against the washer. Sure, this is a lot of messing about, but at the end of the day I've eliminated the only other alternative; a nut and bolt, which just looks plain wrong. Successful use of this approach should fool the most fastidious judge, suggesting that the gearbox has never been messed with. That's the plan anyway. Thanks Graeme for your research. Cheers Peter TD 5801 |

| P Hehir |

| Very interesting link Peter. I'm pretty certain that "forward" means rotating in the direction to drive in a right hand threaded screw. What I haven't figured out is how one clamps a screw or bold with a head into a Jacobs chuck and keeps it centered and vertical. It might be necessary to make a collar that is thick enough to be proud of the screw or bolt head but then how do you keep the screw or bolt from turning in the collar? Perhaps a split collar so that the chuck can squeeze it tight to the working stock.

Just curious. If you use this technique, let us know how it goes. Jud ps: Just for grins, I've attached a pic of what you are trying NOT to do.

|

| J K Chapin |

| Thanks Jud. Yeah... It's not pretty. :-) Cheers Peter TD 5801 |

| P Hehir |

| Quote" What I haven't figured out is how one clamps a screw or bold with a head into a Jacobs chuck and keeps it centered and vertical End Quote. Take one or two nuts, Cut a slit with a hacksaw on one face, into the threads. Under compression they will now clamp on the threads. Thread them on so the slit is NOT clamped by the chuck. Tighten. I use a piece of 1/2" diameter hex stock, I drill and thread it. I cut it long enough so the bolt does not wobble. Then slit it. Jim B. |

| JA Benjamin |

Close up with iPhone of rivet in my 1971 NOS Smiths tach drive. Looking with loupes, it is definitely a round rivet, hollowed out near the end that was then peened over with a sharp hexagonal tool. The inner part just below is positively round and smooth. The problem I recall with rivets here is that as there is no internal spacer, the case crushes inward and then everything binds. That is why I have seen a lot with self lock nuts or double nutted with screws.

|

| George Butz III |

| You're right George about the potential for crushing and binding. The key has to be finding the correct relationship between the wall thickness, the class of steel, the depth of the hollowed tail, the peening tool and the force needed to peen the wall over the washer. But at less than $3 AU for a pack of 20 solid Allen headed bolts with an unthreaded 4 mm shank 20 mm long, I have plenty to experiment with. To counter the potential for crushing, perhaps a 4 mm ID sleeve could be fitted internally to each rivet, assuming this clears the gears.? Cheers

Peter TD 5801 |

| P Hehir |

| Just came accross this thread Peter The rivets look very similar to brake shoe rivets Maybe a visit to your local brake joint There are several different rivet diameters and lengths available--and material brass/steel etc How long are they form under the head to the end- willy |

| William Revit |

| I'll get back to you on that Willy. The 3 gearboxes that are all buggered have been held up in the post. The tracking # shows they are still en route. I'd like to compare their dimensions with the one that I've taken apart. I did see the brake shoe rivets but no mention of steel. I have been told by the major rivet supplier here that all solid and semi-tubular rivets since 1969 have a standard thin head, way less than 2 mm. Cheers Peter TD 5801 |

| P Hehir |

| Do they have to be steel Maybe you could use the hollow half of brass screw nails as used in leatherwork, they have thicker heads I'll see if I can find a sample on ebay for you to lookat willy |

| William Revit |

| Here you go https://www.ebay.com.au/itm/20x-Belt-Screw-Leather-Craft-Chicago-Nail-Brass-Rivets-Stud-Head-Wallet-Round-H/193561343357?hash=item2d1127b57d:g:xVYAAOSwWxxd1NGa |

| William Revit |

| Yeah Willy. Brass is a no no. Steel is original and it is seen so... I reckon I've got it sorted though. Graeme Evans and I have been discussing a method using my drill press which should work. I'll post a pic of an assembled gearbox IF I can get enough good gears from the ones that I have coming. Cheers Peter TD 5801 |

| P Hehir |

| My car was wrecked in the early 60s and sat for over 20 years in a garage. The gent who brought it back to life , to my knowledge, left everything original on the engine and elsewhere when possible, the tach gearbox has the rivets with the hex holes on the ends. I can't read the number without removing it, so for now that's all I can say about it. Is it original, I guess but don't know for sure. PJ |

| PJ Jennings |

| Couple of issues with the Allen head screw bolts mentioned above. When the 'pack' arrived it wasn't a pack of 20, just a pack of 1. Probably a good thing as when I linished the head down to remove all traces of the Allen key recess, all that remained was a flat head 1 mm thick! These 1 mm solid rivets are commonly available and the semi-tubular are much less so, but both are unsuitable and therefore unusable for my purpose.

Also Googling 4 mm bolts just produces images of set screws and machine screws that are invariably threaded all the way to the head. I'd always understood that a bolt had a shank and that a machine screw or a set screw did not. Seems that real bolts with a 4 mm shank are not available. So it appears the only resort is to have these turned up on a lathe, perhaps starting with the smallest diameter bolt that actually IS a bolt, (one that has a suitable length of unthreaded shaft), insert the head in a lathe, reduce the shaft to the correct length, use a centering bit to produce the hole in the tail for peening, reverse the item securing the shaft and then reduce both the diameter and height of the head to the desired 7 mm diameter x 2 mm high. I refuse to use a bolt and nut except to test the function before the tail is heaxagonally peened. Open to other suggestions that will produce an original looking semi tubular hexagonally peened rivet. Cheers Peter TD 5801 |

| P Hehir |

| I reckon your cap screws would have been too hard anyway, they're usually grade 5 or 8, i'm thinking you need something softer like mild steel

Easier to knock them up out of some 8mm rod Drill the hole ,spin down to 4mm to the required length, spin the head down to 7mm and part off at 2mm length----done----5 mins work Do you have a suitable hex setting punch Just out of interest, how long are they from under the head to the end, looks like around 13mm from here and what size drill slides through the hex to the end of the hole and how deep is the hole Is the hex tapered or straight and how far in does the hex go just to complete your earlier set of measurements |

| William Revit |

| Willy if I had a lathe I agree it'd be a doddle. The three buggered tachos have arrived so I can now confirm measurements from all four. I'll post them tomorrow. Bit late tonight. Matt Damon is playing Carroll Shelby on Foxtel. Just paused for a cuppa. The "punch" is one of a set of about 100 bits in a wild variety of shapes including one that will reproduce the original looking tail. They aren't designed to act as a punch but I can't see why the bit can't be used that way even if I do end up stuffing it. It's not like I'm going into production. If I end up with two or three good looking and functional ones, I'll be happy. The wall section that's being peened is 1/2 mm thick and the depth about 1 mm. Cheers

Peter TD 5801 |

| P Hehir |

| Peter I have emailed you some options. Graeme |

| G Evans |

| Thanks Graeme. I'll call you tomorrow to discuss. Thanks mate. Cheers Peter TD 5801 |

| P Hehir |

| Had a few spare mins last night waiting for the Tour to start on telly- HOW GOOD IS PICHIE PORTE--magic ride by him Anyway,i roughed up a rivet and it's easily doable If you want i can make you some but not interested unless i have dead acurate measurements or preferably a sample to work from- not interested in doing half a job willy

|

| William Revit |

| Sorry Wily for not contacting you as I spent most of the day sorting the details for the Injection Moulding Machine that TTORC is building. I'll run my digital Vernier over the one box that I've taken apart and provide the additional dimensions that you require. I appreciate the offer. Cheers Peter TD 5801 |

| P Hehir |

| Hi Willy. The rivet dimensions are detailed in the accompanying picture. The material is attracted to a magnet so it isn't stainless steel. There is no sign of rusting. Once the peened area was carefully straightened it was difficult to be totally precise about the overall length including the head, but 14.6 mm is as accurate as I could measure. The rivet shaft is very close to 12 mm or perhaps fractionally under. The overall assembled case varies between 10.83 mm to 10.55 mm thick. No two measurements around the item were the same. The depth of the hole was also difficult to measure. I used a pointed toothpick and measured the buried depth. My guess is the wall thickness of the peened area is about 1/2 mm. I hope that this, along with the dimensions posted earlier is enough for you to play with. Obviously the washers can be reused. Once assembled the rivets and washer will turn as a unit but will still securely hold the case together. Much appreciated. Thanks. Cheers

Peter TD 5801

|

| P Hehir |

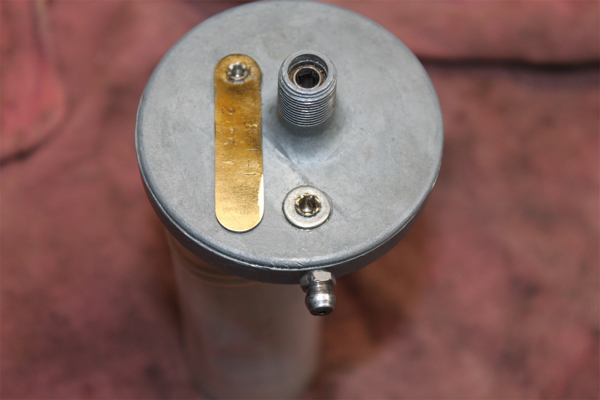

| Hi all Here is a shot of rivets and the setting tool in process of being made. I also made a toll to make the thrust washers that go under the gears. I'm rebuilding two gear boxes right now. Butch T

|

| R Taras |

| The rivets look good Butch. Are you able to confirm the dimensions? This would be a big help to the members of our club here who are looking to rebuild these for themselves. M.G. TTORC Inc is a registered not for profit association here in NSW. Many thanks. Cheers Peter TD 5801 |

| P Hehir |

| Butch The measurements of your rivets match Peter's fairly well---only 2 differences really to which Peter did say his were approx So just to confirm if I could please-------- Hole--2.5mm Length of the rivet from under the head--13.8mm The hole size I agree with. The length of the rivet, is this an estimate or did you manage to successfully straighten out a rivet to measure this Thanks willy |

| William Revit |

| Hi Willy. See the attached drawing. The rivets are new, but I got them from a friend many years ago. He has passed so I can't ask where he got them or if he made them. The biggest problem I come across is that the bushing in the case on the input end gets worn. This comes from the box being loose on the generator end. Then the bushing wears and bushing needs to be bored out and a new bushing pressed in place. The loose bushing allows the small gear to move away from proper mesh with the large gear and makes it wear to the point of not meshing and being stripped.

Sorry about the dimensions but we still use the old system here. Butch

|

| R Taras |

| Maybe,? The heads don't look correct, ?? https://www.rivetsonline.com/rivets/semi-tubular-rivets#:~:text=Semi-tubular%20rivets%20%28also%20known%20as%20tubular%20rivets%29%20are,hole%29%20to%20roll%20outward%20when%20force%20is%20applied. |

| PJ Jennings |

| Hello PJ. There are many types of semi-tubular rivets. On the web site you reference they only have oval and truss head. Countersunk head is another that is available. When I contacted one of the rivet suppliers recently they said that nail head semi-tubular are a special order now. Butch |

| R Taras |

| Thanks Willy and Butch for your invaluable help. Others here will clearly benefit from your experience. PJ trying to find these rivets has been like chasing fog. Graeme will attest to that. I tried my 'go to' second hand engineering supplier in Stanmore but even he couldn't help and this guy has a huge warehouse full of just about every engineering item you could ever want. Butch is on the money in that the only way to get them today is to either make them or have them made. Thanks also for the tip about the bushing. Manufacturers would charge the earth for a small run of these rivets or probably wouldn't even be bothered. I'm hoping a few more TTORC members put their hands up to make some of these and that they can then be distributed free to our members. I really do regret not owing a small lathe! Perhaps the club may have the finances in a year or two to buy one, or members may even be able to use the resources of one of the Men's Sheds to knock a few up. :-) Cheers

Peter TD 5801 |

| P Hehir |

| Hi Peter. I'm glad to help. I'm glad that I have machines here at home. I rebuild a few parts and make parts. Butch |

| R Taras |

| Thanks Butch

It'd be really nice to know for sure if these rivets were originals or manufactured , but as you say we have no way of knowing They're simple to make but the overall length is the question to me- Peter's thickest g/box was 10.83mm then the washer another 1mm so 11.83--this leaves roughly 2.4 mm poking out past the washer to set with the punch if the rivet shaft is 14.22mm ---seems a lot but them rivets came from somewhere, I'm thinking if you've had them for several years they are probably originals so I think 14.22mm might be the best length to go for Might have to rethink the length Peter, see how they go willy Thanks again Butch--very helpful info- |

| William Revit |

| OK Willy. Thanks again for all your help. Cheers Peter TD 5801 |

| P Hehir |

| Peter Did you check out the "Build a Rivet" section within the web site PJ Jennings posted. Also some interesting dimensions particularly the clinch allowance specs. Graeme |

| G Evans |

| Interesting Graeme, had flicked through and missed that On the s/tubular rivet chart the clinch spec seems to average around 2/3 the dia. of the rivet meaning around 2.5mm for these 4mm rivets Butch's rivet length is looking better all the time and I'm more and more suspecting they are originals Will wait till Peter checks the samples but copying Butch's specs looks more like the way to go Cheers willy |

| William Revit |

| The thing to remember is standard setting practice for semi-tubular rivets is to roll the end over to press on the washer. The rivets on the tach gearbox are flared out, not rolled like a standard setting of a semi-tubular rivet. Butch |

| R Taras |

| Yep, I've just blown one of Peter's pics up as much as i can and it shows the finished rivet at roughly the same thickness as the washer (1mm) and is flared out at about 45 deg. so would have been 2mm or so proud of the washer prior to being set so would need to be 14mm long at least--same length as your rivets--I reckon they're originals, and now we have the measurements to make exact replicas Thanks again willy

|

| William Revit |

| Hi everyone. I just set two of the rivets and it appears that the length of the rivet is too long by about .050 or 1 mm. The rivet spreads too far out when set to the proper tightness on the case. Also on close examination the tubular part of the rivet appears to be made on a heading machine. The bottom of the tubular part is flat. It does not have a angle at the bottom of the hole that a drill would leave. Butch |

| R Taras |

| Thanks for the clarification on the dimensions Butch. Mine have arrived from Willy but yet to find the time to clean up the gunked up tacho drive and test them for length. Cheers Peter TD 5801 |

| P Hehir |

| Butch To produce a flat bottomed tubular hole just grind up a square ended same diameter drill and run it into the end of the existing rivet hole. Graeme |

| G Evans |

| Hi Graeme. The bottom of the holes are smooth. I'd just use an end mill since the web in the center of the drill wouldn't cut without a lot of work with a grinder on a small area. Though I don't think that a judge at a concours would look in the rivet to see if the bottom of the hole is flat or drilled. Butch |

| R Taras |

| Now that did make me laugh. Nice one Butch. I'm very much of the "out of sight out of mind school". Cheers Peter TD 5801 |

| P Hehir |

| Hi all. Just finished the tach boxes. I changed the length of the rivet from .560 to .500 and it flares properly as shown in the previous photos. All other dimensions are the same. Butch |

| R Taras |

| Butch can you post a pic of your peened over rivet tail on one of the assembled tacho boxes? The tool you made looks great! Cheers Peter TD 5801 |

| P Hehir |

| Cheers Butch, Thankyou for the feedback .500 |

| William Revit |

| Hi All. Here are the pictures you requested. The setting tool is shown with the holder that goes in the hydraulic press. I have better control in the press then by hand and can tell that the rivet is set correctly when it doesn't rotate in the housing. Butch

|

| R Taras |

| Nice result young man---------that looks spot on to me, .500" is the target length then Cheers willy |

| William Revit |

This thread was discussed between 17/08/2020 and 06/10/2020

MG TD TF 1500 index

This thread is from the archives. Join the live MG TD TF 1500 BBS now