MG-Cars.info

MG TD TF 1500 sway bar BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

MG TD TF 1500 - sway bar

| I'd like to install a sway bar on my TD. I've seen two different configurations. One has the spring pan and the wishbone arm reinforced were the link attaches. The other has a piece of angle iron bolted to the side of the wishbone arm and the link passes through it. This seems to be an easier installation, but I question the strength of the single bolt. I've also noticed a differe4nce in the ends of the sway bar--some have a vertical end with a horizontal hole and others have a horizontal end with a vertical home.

Please explain the pros and cons of the different configurations. What has been your experience. |

| R Maitzen |

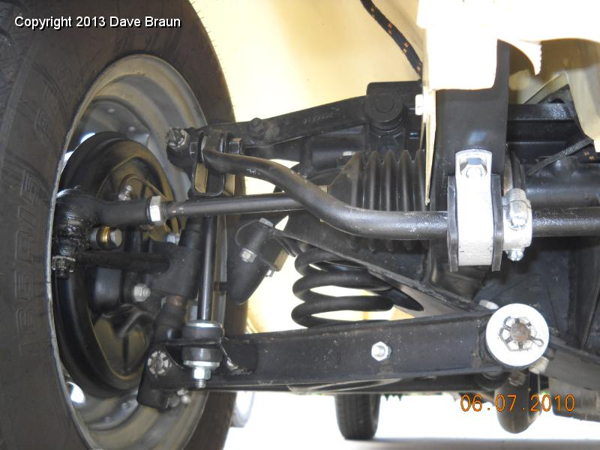

| My install looks like this: I used GM links to a custom welded bracket that required adding one hole in the front a-arm and pan. The anti-sway bar is a 9/16 dia from a 1970 MGB GT. No problems in 25000 miles.

|

| Dave Braun |

| Here are the brackets that hold the sway bar mount to the dumb irons. The anti-sway bar made the car much more fun to drive, and dampened the steering bounce. My website has the complete story.

|

| Dave Braun |

| See http://www.ttalk.info/ARB_systems.htm . LaVerne's approach is directly from MG components. Installation videos can be viewed. Bud |

| Bud Krueger |

| LaVerne's set up worked perfectly for me. I also shortened the drop links to pass under the steering gear and modified the TF spring pans by welding on a tab of steel instead of buying MGB spring pans. Dave H |

| Dave Hill |

| If you watch LaVerne's videos on my TD note that we put something on backwards because it was "handed". We to redo it a few days later. Sorry I don't remember more. Ed |

| efh Haskell |

| It's the upside down front a-arms, Ed. The trapezoid plate that's welded over the hole for the link needs to have the wide end down, not up. I've tried like mad to change those texts, but to no avail. Bud |

| Bud Krueger |

| I used all MGB components. Bar,links, pans, mountings. All in modified with the bar over the steering arms. Straight forward install with no interference with steering linkage. I used the 5/8" bar. It helped with sway but I wished I'd used a heavier bar for the type of driving the car s intended use would be. May upgrade at a later date once I get the engine sorted to my liking. |

| W A Chasser |

| I wish I knew how Bud. |

| L E D LaVerne |

| Wide end down or wide end up is going to be more than strong enough. Dave H |

| Dave Hill |

| It also affects the vertical location of the link. The hole is not centered on the a-arm. Bud |

| Bud Krueger |

| True, but I am not sure it makes any difference that matters. Dave H |

| Dave Hill |

| It does make a difference Dave which is why we had so much difficulty getting the bolt in during the video. |

| L E D LaVerne |

| Ok, that's the proof that I was looking for, though if you modify your own spring pans as I did you can put the large mounting hole anywhere. In fact I have been out to my garage to check mine to see which way I did it and they are wide side down. Dave H |

| Dave Hill |

| X2 Dave, except mine are DIY load spreading braces wide side up! I don't think it's a 'mission critical' component, just a matter of getting it to fit unless someone is going to run the calculations to see if it is strong enough. I think there are enough in service with no failures reported to render that unnecessary. Chris |

| C I Twidle |

| I believe that Edney says to use the original T type pans and not bother with the MGB type - that's the way he builds them and no issues. The only other comment I heard was from Ron Gammons who said to make sure you use high quality bolts between the pan and the wishbones as they are highly loaded. Dave H |

| Dave Hill |

This thread was discussed between 06/09/2017 and 09/09/2017

MG TD TF 1500 index

This thread is from the archives. Join the live MG TD TF 1500 BBS now